Cartridge Manipulation

Exploring the necessary cartridge modifications began with taking the cartridge apart. To break open the cartridge, I simply tapped lightly with a flathead screwdriver and a hammer, around the top edge of the cartridge at the intersection of the lid and the base. After tapping the screwdriver into the groove, the cover would gradually work its way off, though cracks would occur in the plastic around the top edge. These cracks did not prove detrimental to the functioning of the cartridge.

The HP5700 used HP94 black ink cartidges and HP95 color cartridges (shown below). Within both, there were sponges that held the ink. At the base of each sponge was a small well (~0.5 mL in volume) that was covered by a thin filter.

Lid removed from an HP95 color ink cartridge

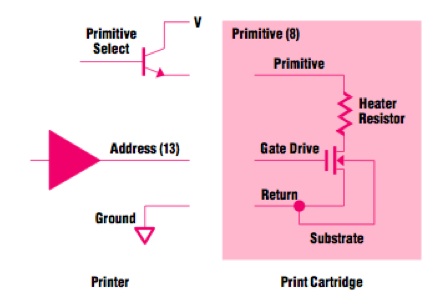

Within each cartridge is a series of tiny nozzles, each which have a small heater which allows for the creation of ink droplets. The current across the heat resistor creates a flash of high temperature, which causes instant vaporization of the substrate. A simplified schematic (courtesy of HP) is shown below. Note that additional information and a useful resource is available at http://wandel.ca/hp45_anatomy/index.html, which provides an in depth description of the dissection of an ink cartridge.

Circuit schematic of ink cartridge nozzle

In order to ensure that the cartridges could print cells, a series of experiments was necessary. Throughout these experiments, I made a series of key estimates.

Experiment 1: New Ink

Key Question Can a different aqueous solution flow easily through the cartridge?

Design In a simple first experiment, I removed the sponges and emptied the cartridges of their ink, washing multiple times with water to remove as much ink as possible. I then filled the chambers with about 2 mL each of different colored ink made with food dye.

Results Images came out properly printed but with the new color ink, verifying that different inks could be passed through the cartridge.

Note: It is helpful to empty the ink from a new cartridge because each cartridge has a limited printing lifetime which is tracked by the computer. Even if a cartridge has ink in it, the printer may think it is empty because it has theoretically expended enough ink to render it no longer functional.

Experiment 2: Cartridge Flow Test

Key Question How much ink must pass through the cartridge before a new ink begins flowing through the printer?

Design After cleaning out the cartridge thoroughly with water and ethanol and letting it dry, the cartridge was loaded with 2-3 mL of new dye. The printer was then printed at a maximum dpi in a solid square to determine at what point the ink would start flowing.

Results The ink created a solid patterned square after printing about 0.75 square inches.

Assuming a drop size of 50 pL, then $ 1200*1200*0.75=1.08*10^6 drops $ and $ 1.08*10^6*50*10^-12 = 60*10^-6 $ or about 60 microliters.