DNA Melting Part 2: Lock-in Amplifier and Temperature Control

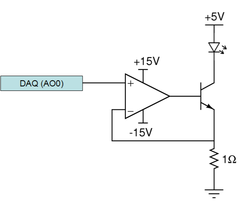

LED driver

The LED used in this lab can consume 1.5 Amps of current when driven to its full range, but this is more than 10x the light you will need. In fact, you will need only roughly 100 mA, but even this low current is 50x what the analog voltage output sources in the 20.309 USB-6212 DAQ systems are capable of driving. And even if there were enough current available, the steepness of a diode's I-V curve results in large swings in current for small changes in supply voltage. LED radiant flux is proportional to current, so a current source tends to provide a more stable light output.

To implement a current source to drive your LED, you will be using a Darlington Transistor. This is a special device in which one transistor drives another to provide higher input-output current gain. At the LED current levels for your instrument, the TIP120 will be providing a current gain of about 500. A transistor is a three terminal device in which the voltage or current at one terminal controls the voltage across, or current through, the other two terminals. In our case, the TIP120 acts like one BJT consisting of a Base, Emitter, and Collector, and should be wired into the circuit shown in the diagram. We will use the base contact of our TIP120 to accept a small amount of current from an op-amp, which will cause the TIP120 to conduct a much larger current between it's collector and emitter, in turn allowing nearly the same level of current to flow through the LED.

As described in lecture, the op-amp will be used to linearize the behavior of the TIP120. Here the LED and transistor are inside a feedback loop extending from the output of the op-amp, through the base-emitter conduction path in the TIP120, and back from the top of the 1 Ohm resistor, whose voltage drop is thus fed-back to the negative input node of the op-amp, completing the loop. Recall that this is simply a buffer implementation, with gain of 1, where the feedback voltage is directly proportional to the LED current. Notice that in this way the current through the LED is exactly equal to the voltage applied to the op-amp positive input by the DAQ. (Remember the golden rules.)

Note: if the LED is too bright then the sample will become photobleached very quickly. In the Labview VI for Part 1, you are able to set the voltage supplied to the op-amp.

Note also that the voltage to the LED comes from the fixed 5V supply on your lab station's INSTEK GPS-3303 power supply, modulated by the TIP120, whereas the op-amp operates on +/– VCC (+/-15V in your setup).

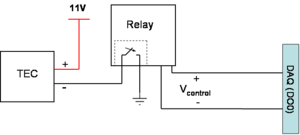

Heating control

We will use a thermoelectic cooler (TEC) to heat the sample in this lab. A TEC is a device that becomes warm on side and cold on the other side when a DC voltage is applied across it. Before heating the sample, make sure that the TEC makes good thermal contact with the heating block. If there is not good thermal contact, hot spots will develop, damaging the TEC. To ensure good contact, use the MINIMUM amount of thermal grease, and make sure that the heating block lies flat on the TEC. Wooden sticks are available in the DNA Melting drawer (far right of the prep bench) to help you apply an very thin layer.

To control the TEC in this part of the lab we will use an optically isolated switch, controlled by the Labview VI for Part 1. The diagram shows the suggested schematic for the lab.