Difference between revisions of "Confocal Wiki"

(→Circuit Design) |

(→2.2 Circuit Setup) |

||

| Line 42: | Line 42: | ||

[[File:Confocal Circuit Diagram.JPG|center|thumb|600px]] | [[File:Confocal Circuit Diagram.JPG|center|thumb|600px]] | ||

| − | ''' | + | '''(B)''' PMT Circuit: In order to create a confocal image, the temporal array of PMT signal intensities must be reconfigured into a 2D image based on the scan of the sample. The current generated by the PMT is low and must be amplified. The gain of the PMT circuit is: |

| − | + | ||

| − | |||

| − | |||

| − | + | The resistors were chosen to amplify the PMT signal so the output to the DAQ is between 1-10V, and consistently less than 10V (since that is the maximum voltage the DAQ can read). | |

| − | + | ||

| − | + | ||

| − | The | + | The capacitor was chosen to act as a low pass filter to minimize shot noise. |

| − | + | The oscilloscope measures the voltage coming out of the Op Amp. Since the voltage from the PMT is negative, the voltage measured from the output of the Op Amp will be positive. The oscilloscope measurement is taken from the Op Amp output in order to prevent interfering with the amplification circuit. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | The | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | (A) Photodiode Circuit: Similarly, the signal from the photodiode is amplified to be in the range of 1-10 V. The gain is: | ||

| + | |||

| − | + | (E) Stepper Motor Driver | |

| + | In order to take 3D scans of samples, the Z-axis of the stage is connected to a stepper motor which allows the sample to be moved incrementally along the Z-axis. The stepper motor is controlled by the DAQ through the stepper motor driver which transmits voltage signals from the MS1, MS2, MS2, DIR and STEP pins to motor coils 1 and 2 through pins 2B, 2A, 1B and 1A. The input the the driver from the DAQ is described in the table below. | ||

Revision as of 23:34, 23 May 2011

Contents

Measuring Morphology of Biological Specimen using a Low-Cost Confocal Microscope: An Undergraduate Teaching Experiment

Stephanie Bachar, Sivakami Sambasivam, Steven Wassermann and Steven Nagle.

1 Motivation

1.1 Background and Motivation

The main advantage of a confocal microscope is its ability to image a very narrow depth of field, advantageously excluding light from above or below the focal plane of the image. This is done by using a pinhole, strategically placed where the light from the focal plane comes to a focal point while light from below and above the sample is converging or diverging. As a result, confocal microscopes have increased contrast compared to wide-field microscopes. Additionally, they can be used to generate 3D images by taking a series of 2-dimensional images along the z-axis of a specimen. Also, confocal microscopes have a marginally higher resolution than wide-field microscopes.

Currently, confocal microscopes cost on the order of $100,000 - quite an expensive purchase for a teaching laboratory or a low budget laboratory. Recently, there has been a new advent of creating low-cost imaging systems to allow for higher quality imaging in resource constrained environments. Xi et. al (2006) created a $8561 addition to a $20,000 inverted microscope allowing confocal imaging at a much lower cost than confocal microscopes available on the market. Further, researchers at the Massachusetts Institute of Technology have created an atomic force microscope that costs less than 10% of research-grade atomic force microscopes and other MIT researchers have created a cost-efficient optical trap for use by undergraduates.

The objective of this project is to create a teaching confocal microscope with associated documentation and suggested experiments for approximately $20,000. Based on our literature review, such a system does not currently exist.

1.2 Previous MIT Prototypes

In Fall 2009 of 20.309, Laskey, Ramanthan, Rurak and Wilder began the construction of a confocal microscope in the 20.309 laboratory. Stephanie Bachar continued work on the microscope during January of 2011. When beginning our project, the confocal microscope was functional but had a number of imaging and processing limitations. There were also a number of additional components which could be added and characterizations which could be performed to augment the device.

There were some stability issues in the optical setup, as well as unnecessarily complex construction. The signal generated by a fluorescent reference slide was about 2V, which is somewhat low. The images generated by the confocal microscope had blurry edges and inconsistent intensity due to fluctuations in the laser output. While there had been successfully imaged patterns on a fluorescent reference slide, the setup was unable to pick up signal from fluorescent beads. This was likely due to the resolution capabilities of the microscope as well as the low density and dimmed fluorescence of the beads used. Matlab code existed to generate a laser scan over the sample and to recompose the associated output from the PMT into an image. However, the scanning and re-composition code was quite inefficient, resulting in very slow image generation. Furthermore, the scan code generated a single 2D image of the sample instead of 3D imaging.

2 Design

2.1 Optical Setup

A confocal microscope generates images of sample fluorescence by scanning a laser across the field of view. The fluorescent signal at each point of the scan is measured by a photomultiplier tube and the intensities of the signal are used to recompose a fluorescent image. Each component of our optical design is described below.

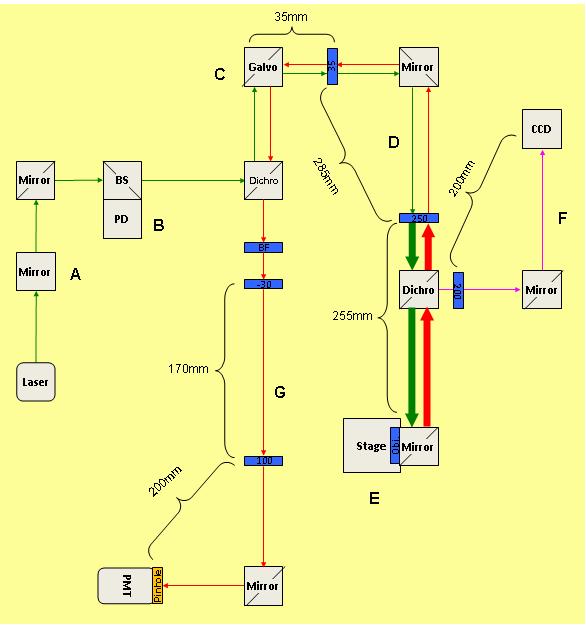

(A) Our setup uses a 532nm laser with beam diameter of 1.1mm. (C) The laser is shone onto a dichroic which reflects the 532nm light of the laser into 2D galvanometer scanning mirrors. The galvos scan the laser back and forth across the desired field of view and at the desired resolution. (D) The laser beam diameter is expanded 7.14-fold by the 35mm, 250mm lens beam expander. The larger the beam diameter going into the objective, the smaller the beam size on the sample plane. The 35mm lens is placed ~35mm away from the center of galvos to ensure that the angle of deflection of the laser as it is coming out of the galvos is the same angle as the beam entering the objective lens. The 35mm lens is placed (35mm+250mm=) 285mm away from the 250mm objective lens to ensure that the light exiting the beam expander is collimated. (E) The beam is focused on the sample plane using a 40x objective. Fluorescence signal traces back through the beam expander (which shrinks the beam 7.1-fold) and the galvos and then passes through the dichroic. (G) The fluorescence signal is passed through a barrier filter to exclude any reflected laser light and through a 6.7-fold beam expander. Finally, the beam is focused such that the signal from the plane-of-focus of interest comes to a focus at a small pinhole (20-50um), thereby excluding out-of-focus light. The photons from the beam reach a photomultiplier tube (PMT) which translates the intensity of the fluorescence into current.

(B) We additionally measure the laser output to correct for variation in laser intensity. A fraction of the laser beam is diverted using a beamsplitter (a microscope slide cover slip) into a photodiode which reads the laser intensity.

(F) Finally, the microscope images bright-field as well. A near-IR LED illuminates the sample. The bright-field image is reflected off of an IR dichroic and focused onto a CCD camera by a 200mm tube lens.

Design Considerations The 35mm lens is a positive lens not a negative lens because the beam expander also serves as a relay lens, thereby keeping more of the laser scan within the confines of the 1” optics.

We chose a 7-fold expansion for the laser beam because this approximately fills the maximum diameter of the 40x objective, thus minimizing the size of the scanning beam spot.

Suggestions for changes It may be beneficial to have two beam expanders, one before the galvos and one after the galvos. This will shorten the beam path needed for the laser beam expansion leading to the objective as well as the beam expansion needed for the fluorescent signal leading to the PMT.

It should also be possible to use a 100x objective lens with minimal changes. This will give better resolution images. However, 100x objective lenses are more difficult to use since the ones we have in lab are oil immersion lenses. Thus, they should only be used when most of the rest of the microscope has been worked out.

2.2 Circuit Setup

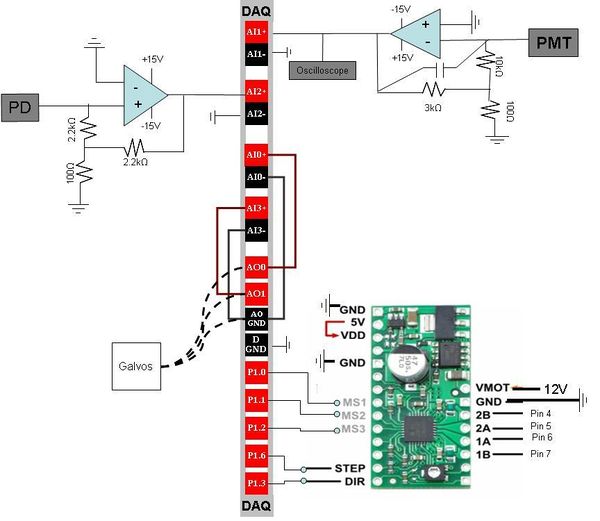

(B) PMT Circuit: In order to create a confocal image, the temporal array of PMT signal intensities must be reconfigured into a 2D image based on the scan of the sample. The current generated by the PMT is low and must be amplified. The gain of the PMT circuit is:

The resistors were chosen to amplify the PMT signal so the output to the DAQ is between 1-10V, and consistently less than 10V (since that is the maximum voltage the DAQ can read).

The capacitor was chosen to act as a low pass filter to minimize shot noise.

The oscilloscope measures the voltage coming out of the Op Amp. Since the voltage from the PMT is negative, the voltage measured from the output of the Op Amp will be positive. The oscilloscope measurement is taken from the Op Amp output in order to prevent interfering with the amplification circuit.

(A) Photodiode Circuit: Similarly, the signal from the photodiode is amplified to be in the range of 1-10 V. The gain is:

(E) Stepper Motor Driver In order to take 3D scans of samples, the Z-axis of the stage is connected to a stepper motor which allows the sample to be moved incrementally along the Z-axis. The stepper motor is controlled by the DAQ through the stepper motor driver which transmits voltage signals from the MS1, MS2, MS2, DIR and STEP pins to motor coils 1 and 2 through pins 2B, 2A, 1B and 1A. The input the the driver from the DAQ is described in the table below.