Difference between revisions of "20.109(F15):Purify active materials (Day2)"

Noreen Lyell (Talk | contribs) (→Introduction) |

Noreen Lyell (Talk | contribs) (→Introduction) |

||

| Line 4: | Line 4: | ||

Biomineralization is a process by which living organisms generate minerals that are often used to harden soft tissues. In our work for module 3 we are using M13 as a template for the biomineralization of phosphate to be used in your Na(FePO<sub>4</sub>) cathode. | Biomineralization is a process by which living organisms generate minerals that are often used to harden soft tissues. In our work for module 3 we are using M13 as a template for the biomineralization of phosphate to be used in your Na(FePO<sub>4</sub>) cathode. | ||

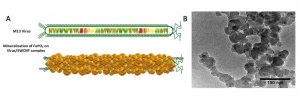

| − | [[Image:Fa15 20.109 biomineralization M3D2.png|thumb|center|300 px| '''M13 biomineralized with FePO<sub>4</sub>.''' (A) Schematic view of M13 before and after biomineralization. (B) TEM image of biomineralized M13 showing FePO<sub>4</sub> particles ranging in size from 10-30nm. This image was modified from [http://pubs.acs.org/doi/abs/10.1021/nl504676v Moyadi et al. 2015]. | + | [[Image:Fa15 20.109 biomineralization M3D2.png|thumb|center|300 px| '''M13 biomineralized with FePO<sub>4</sub>.''' (A) Schematic view of M13 before and after biomineralization. (B) TEM image of biomineralized M13 showing FePO<sub>4</sub> particles ranging in size from 10-30nm. This image was modified from [http://pubs.acs.org/doi/abs/10.1021/nl504676v Moyadi et al. 2015].]] |

The use of M13 as a 'scaffold' for this reaction is also termed biotemplating. Biotemplating utilizes biological materials to fabricate and/or organize unique nanomaterial structures. A variety of benefits are associated with biotemplated synthesis methods over traditional synthesis methods. From the fabrication standpoint, biotemplating can reduce the environmental impact of materials synthesis. Biotemplating has been shown to enable synthesis of materials at lower temperatures and pressures as well as using milder reagents than traditional synthesis methods. From the stand point of organization, biotemplating can achieve unique structures over broad length scales. These structures are either unattainable or significantly more difficult to create without biotemplating. | The use of M13 as a 'scaffold' for this reaction is also termed biotemplating. Biotemplating utilizes biological materials to fabricate and/or organize unique nanomaterial structures. A variety of benefits are associated with biotemplated synthesis methods over traditional synthesis methods. From the fabrication standpoint, biotemplating can reduce the environmental impact of materials synthesis. Biotemplating has been shown to enable synthesis of materials at lower temperatures and pressures as well as using milder reagents than traditional synthesis methods. From the stand point of organization, biotemplating can achieve unique structures over broad length scales. These structures are either unattainable or significantly more difficult to create without biotemplating. | ||

Revision as of 13:54, 16 November 2015

Contents

Introduction

Biomineralization is a process by which living organisms generate minerals that are often used to harden soft tissues. In our work for module 3 we are using M13 as a template for the biomineralization of phosphate to be used in your Na(FePO4) cathode.

The use of M13 as a 'scaffold' for this reaction is also termed biotemplating. Biotemplating utilizes biological materials to fabricate and/or organize unique nanomaterial structures. A variety of benefits are associated with biotemplated synthesis methods over traditional synthesis methods. From the fabrication standpoint, biotemplating can reduce the environmental impact of materials synthesis. Biotemplating has been shown to enable synthesis of materials at lower temperatures and pressures as well as using milder reagents than traditional synthesis methods. From the stand point of organization, biotemplating can achieve unique structures over broad length scales. These structures are either unattainable or significantly more difficult to create without biotemplating.

Protocols

Part 1: Demo of phage biomineralization reaction

Because the initial step of the biomineralization process is time-sensitive, George quenched your reactions after ~12 h by adding 100 mL of 1 mM Na:PO4. In this step, the phosphate precipitated the Fe(III) onto the p8 proteins of the M13 phage coat to generate the nanowires that will be used to construct the cathode of your battery. So you can see this reaction, George has prepared a small sample as a demo.

Part 2: Collect active material (nanowires)

In your flask are the Fe(III)-phage biomineralized nanowires that will serve as the active material in your battery cathode. Today you will isolate and wash this material.

- Retrieve your flask with your Fe(III)-phage nanowires from the front bench.

- Gather the nanowires that adhered to the side of your flask.

- Use a P1000 pipet to 'waterfall' the culture liquid from your flask down the sides of the flask.

- Divide the liquid in your flask equally between two 50 mL conical tubes.

- Be sure to clearly label your tubes with a marker as stickers will come off in the centrifuge.

- Centrifuge at 3,250 rpm for 20 minutes.

- Decant the supernatent in the sink.

- Carefully remove any residual liquid with your P1000.

- Resuspend your pellet in diH2O.

- Add 2 mL of diH2O and mix by pipetting up and down ~10 times.

- Continue adding 1-2 mL aliquots of diH2O and pippetting to mix until you reach a final volume of 5 mL in each tube.

- Transfer the resuspended nanowires from both 50 mL conicals to the same 15 mL conical.

- Be sure to clearly label your tube.

- Centrifuge at 3,250 rpm for 20 minutes.

- Decant the supernatent in the sink.

- Resuspend your pellet in 10 mL of diH2O.

Part 3: Prepare TEM grid with nanowires

Each group should prepare a TEM grid. You will visualize your nanowires on M3D4 with Angie and George.

- Vortex the nanowire pool for 1 minute at least and immediately remove 10 ul of the nanowire suspension to place on the silver/black side (not the copper-looking side) of the TEM grid that you have balanced in the specialized tweezers. Treat the grid with care and use the tweezers only on the edge to minimize damaging the delicate mesh.

- Allow the nanowires to settle onto the grid undisturbed for 20'.

- Remove the droplet from the grid by touching the edge with a Kimwipe thereby wicking the solution off the grid.

- Wash the grid by adding 10 uL of sterile H2O onto the grid.

- Allow the grid to sit with water for 3 minutes and then wick dry.

- Wash the grid by adding 10 ul of 100% EtOH onto the grid.

- Allow the grid to sit with EtOH for 3 minutes and then wick dry, if it hasn't air dried.

- Place the grid into the TEM grid holder for safe transport to the TEM facility (13-1012).

Part 4: Dry active material (nanowires)

To further prepare your nanowires for use in your battery, this active material will be dried at high temperatures to remove all liquid.

- Centrifuge your resuspended nanowires from Part 2 at 3,250 rpm for 20 minutes.

- Decant the supernatent in the sink.

- Carefully remove any residual liquid with your P200.

- Cover your tube with aluminum foil and punch a small hole in the top.

- Bring your tube tube to the front bench.

Your tubes will be transported to the Belcher Laboratory and will be placed in a vacuum drying oven at 80°C.

Next day: Cathode construction

Previous day: Growth of phage materials